Call service and repair

Presmann’s reputation has been built by providing excellent service, pre and post installation.

Where issues arise most can be resolved over the telephone and when a call out to the customer’s site is required, we have our staff on standby to visit your bar at short notice. Our service team carry all essential spare parts and components to get your system up and running, so as to minimize the effect your business.

Training

It is one thing being provided a manual, it is another getting the time to read it and implement its instructions.

Presmann’s approach is to train the bar team at your site, using the equipment, as soon as the installation is complete. This allows the bar staff to be confident in the operation of the system and trains them how to train other staff.

Installation

The Presmann installation teams are experienced and professional. All installations, large or small, are planned and discussed in detail with the customer prior to installation.

Our installation teams install our systems throughout Thailand and ASEAN.

Drip trays

Drip trays are available in wide variety of sizes and in most cases made to order often together with a multi tap beer tower.

Drip trays can be built into the bar counter or stay loose on the bar counter.

Drip trays can have glass rinse. In this case a spare coil in the ice bank cooler for cooling the water and a drain is needed. For more details please fill free to contact us.

Pressure regulators

Pressure regulators are needed to apply and control the correct pressure to the beer. Most commonly used regulator is a one-way type but regulators can also be serial connected to allow individual pressure control for each beer in larger installations.

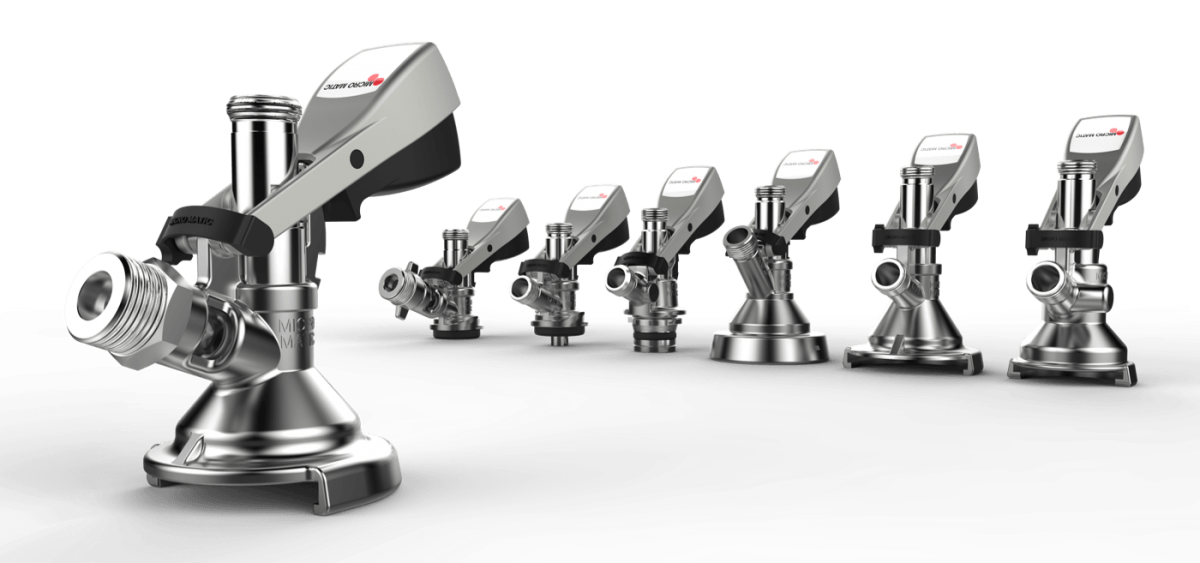

Keg couplers

There is a wide variety of keg couplers in the market. We carry stock of most commonly used keg couplers like A-type, D-type, G-type, S-type and for Key Kegs from top quality brands like Micro Matic and TOF.

FOBs detectors

TecFlo’s FOB detector shuts down beer flow when keg empties. This eliminates the spitting and spraying that usually happens when a keg "blows". No need to refill lines after opening new keg. Eliminating foam and wasted beer. Remember foam is beer (and beer = money).

Air compressors (for Key Kegs)

For beers in Key Kegs compressed air can be used instead of CO2 gas.

For beers in Key Kegs compressed air can be used instead of CO2 gas.

DraftMore

Surely you already know problems with a draft beer installation. Sometimes it can be difficult to keep up with demand because the beer foams too much. It is also difficult to get the last beer out of the keg. Fortunately your problems can be solved with a DraftMore. It makes sure that the pressure in the keg is correct according to the temperature of the beer.

Surely you already know problems with a draft beer installation. Sometimes it can be difficult to keep up with demand because the beer foams too much. It is also difficult to get the last beer out of the keg. Fortunately your problems can be solved with a DraftMore. It makes sure that the pressure in the keg is correct according to the temperature of the beer.